Gooseneck Pull Trailers

Notes

Benefits of Gooseneck: These trailers are all about better stability. The weight distribution is focused on the rear of the truck axles rather than than evenly over the frame of the trailer. The potential for issues with trailer sway are reduced significantly when pulling a gooseneck. Another benefit is the space required to make turns is less. Our gooseneck trailers also allow for adding larger living quarters areas.

You will need heavier towing capacity and more space for storage with this trailer selection. Typically customers looking at these are more experienced at hauling. If being able to pull more with more options is your desire, gooseneck trailer pulls is likely the way to go.

Features:

Hitch – Sand blasted, epoxy primer, finished with urethane paint

Gates – Frame with 3/16 Tubular Material – Doubled under rear cam locks yielding 3/8″ thickness — no collapsing of wall of gate framing when bolted in place

Air Spaces under gooseneck – 12″ H x 20″ W with bars for more air flow and allowing tight seal using rubber seals

Running Boards On Trailers Available – Framed with 2 x 2 and 1 x 2 1/2

Notch Out In Slide Doors – Allows for clean out

Huck Rivets – These rivets are water tight unlike pop rivets, considerably stronger

Side Post are 16″ OC – Post are welded to floor along with welded side posts

Corrugated Side Panel – .105″ thick while competitors typically .008 or .063″ thick, Custom Classic panels have 5 corrugated folds every 7″. You may see others doing 10″ panels with only 2 rounded folds.

Custom Classic Trailers are kick proof – Horses slamming their show into walls are not going to cause damage

Standard | Optional

| Standard Specifications | Optional Specifications | ||

| Length | 20’ – 40’ | Length | |

| Width | 7’ | Width | 6’ 8”, 7’ 6”, 8’, 8’ 6” |

| Height | 6’ 6” | Height | 7’, 7’ 6”, 8” |

| Nose Configuration | 4’ Taper 3003 Aluminum – 0.100 Thick o Welded to Side Posts NOT Riveted | Nose Configuration | Vee Nose Full Width Black, White, Stainless Overlays |

| Center Gate | One (1) w/ Swing Walk Thru Door Hold Up Blocks – Open & Shut Positions HD Slam Latch – Cast Aluminum Outside Slam Latch Release Handle Four (4) HD Extruded Hinges w/ Replaceable Brass Bushings and Stainless Steel Bolt | Center Gate | Two (2) or Three (3) Gates Slider Door Air Gaps per Customer’s Request Lo Pro Center Gates |

| Escape Door | RH 30” Wide Pressure Latch-Cast Aluminum | Escape Door | LH Side Up to 48” Wide Access Hole to Latch from insude |

| Rear Gate | Single Swing Gate w/ Slider Door Five (5) HD Extruded Hinges w/ Replaceable Brass Bushings and Stainless Steel Bolt Cam Latch w/ Safety Chain Two Top Air Gaps | Rear Gate | Double Swing (Both Ways) w/ Slider Door Roll Up Rear Door Double Rear Doors Full Rear Door (No Slider Door or Air Gaps) |

| Side Walls | 1/8” Extruded 6005A Panels 1”x2-1/2” Side Posts on 16” Center 1”x5” Side Posts at Gate Locations, Front and Rear of Subframe, Horizontal over Subframe, Directly Behind Drop Sheet Two (2) Top Air Gaps – Approx. 5-1/2” Wide | Side Walls | Air Gaps per Customer Request |

| Floor | Traction Floor – Extruded 1-3/4”x8” Interlocking | Floor | Crimped Extruded Floor Diamond Tread w/ V Crimps Double Deck Floor |

| Calf Gate | Swing Down – 1 Piece | Calf Gate | 2 Piece Side Swing w/ Center Post |

| Axles | Two (2) Dexter 3,500# on 12’ – 14’ Trailers, Electric Hydraulic/Brakes, Grease Hubs, ST235/75Rx16 Tires, Steel Wheels Two (2) Dexter 8,000# on 28’-34’ Trailers Electric Hydraulic/Brakes, Grease Hubs, 235/75Rx17.5 Tires, Steel Wheels Two (2) Dexter 10,000# on 36’ – 40’ Trailers Electric/Hydraulic Brakes, Grease Hubs 235/75Rx17.5 Tires, Steel Wheels | Axles | Three (3) Axles Electirc/Hydraulic Brakes Disc Brakes Oil Bath Hubs Easy Lube Hubs Chrome Hub and Nut Covers Aluminum Wheels Stainless Steel Simulators 14 Ply Tires |

| Fenders | 8” Board Fender on 7’ Wide 5” Smooth Fender on 7’ 6” Wide 2-1/2” Smooth Fender on 8” Wide Smooth Teardrop Fender on 6’ 6” Wide | Fenders | Diamond Tread Teardrop on 6’ 6” Wide |

| Step/Tie Rails | Step/Tie Rails | 5” Solid Step Rail w/ Anti-Skid Tape Open Tube Step/Tie Rail | |

| Vents | Two (2) Top 5-1/2” Air Gaps | Vents | Multiple Air Gaps per Customer Request Optional Bottom 3” Air Gap – No Charge Drop Sheets Vents w/ Cover Door and Bars Gooseneck Vent w/ Cover Door and Bars Two Way Roof Vents Sliding Corner Vents on Full Width Trailers Drop Sheet Vent Deflector |

| Vent Covers | Vent Covers | Lexan in Any or All Side and Rear Air Gaps Hinged Aluminum Cover Panels Non-Hinged Panels Attached w/ Screws | |

| Lights | One (1) Interior Light w/ Switch on 20’ Trailer Two (2) LED Stop/Turn/Tail Lights on Rear 2” Round LED Rear Marker Lights ¾” LED Button Side and Front Marker Lights o Three Center Front Marker Lights o Three Marker Lights Down Each Side | Lights | Two (2) Back Up Lights – 6” LED Oval Two (2) Rear Load Lights – 6” LED Oval Side Roof Rail Lights Above or Below Fender Marker/Turn Lights Additional ¾” LED Side Marker Lights |

Air vents

| 3 Way Air Vent | Drop Sheet Air Deflector | Drop Sheets Vent | Gooseneck Front Vent |

|  |  |  |

| Gooseneck Vent Bars | Hinged Cover Panels | Lexan Holder | Top and Bottom Side Vents |

|  |  |  |

| Vent Covers | |||

|

Calf Gate

| Calf Gate | Double Calf Gate with Ramp | Split Calf Gate | Standard Calf Gate |

|  |  |  |

Center gates

Escape doors

| Access Hole for Outside Latch | Car Door Escape | Rear Door w/ Access Hole | Standard RH Door |

|  |  |  |

Exterior Walk-tie Rails

| Closed Rail w/ Non Skid Tape | Open Rail | Open Walk and Tie Rail |

|  |  |

Fenders

| 7’ Fender | 7′ 6″ Fender | 8′ Fender |

|  |  |

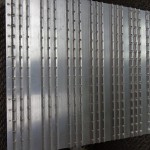

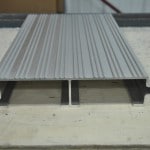

Flooring

| Crimped Floor | Diamond Tread | Standard Extruded I-Beam Floor |

|  |  |

Jacks

| Center Jack | Electric Jack |

|  |

Lighting

| Fender Signal Lights | Fender Turn Signal Light | Interior Light | Lighted Sign Box |

|  |  |  |

| Standard Rear Lights W/ Back-up Lights | Top Load Lighting | ||

|  | ||

Nose style

| 4′ Tapered Nose | Black Skin Overlay | Front Vent Door | Full Width w/ Corner Vent |

|  |  |  |

| Stainless Nose w/ Front Door | Stainless Steel Nose | Standard Nose Lights | Tack Door and Window |

|  |  |  |

| Tapered Nose | V-Nose w/ Side Door | V-Nose | |

|  |  |